Babar

Bigberg

As soon as the Goldberg STL went up I started getting requests for an 8mm version. Eager for another challenge I decided to give it a go.

I know almost nothing of the brushed world, so I ordered some parts recommended by Joel Tempongko and started drawing. I had no idea how much thrust I was working with so I just went for it with no regard for frame weight. The FC is rectangular, so I thought I might as well take advantage of its asymmetry by making a long frame. I started it as a larger Goldberg, with circular prop guards that rose at the edges, and angled struts. It was looking pretty swanky so I allowed myself a stylistic indulgence and connected the prop guards with curved struts.

I made snaps for the FC since it had no mounting holes, and added a cam mount. Then it was on to the battery holder and motor butts.

It sure was pretty (to me at least) for a prop guard frame, but those curved connectors proved to be almost useless. They easily compressed and elongated, adding little rigidity. It was also porky – the top alone was 14.4 grams. When the parts finally showed up I threw them on and found that...it could barely lift off. I was hoping that 8mm motors would be way more powerful, but I guess not.

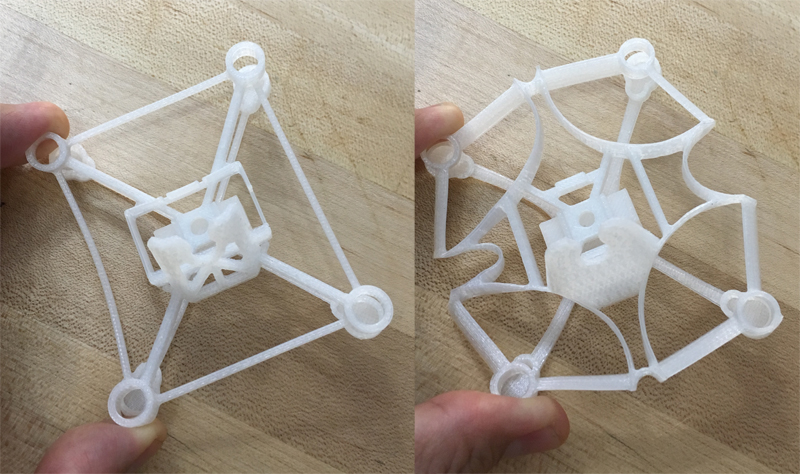

Joel suggested that this could be a 2s option, so I ordered yet more parts for a 2s build, and started re-evaluating the 1s version. It was clear that a 1s rig couldn't have prop guards at all. For a quick test I took the nippers to the guards to see if it would fly.

So unintentionally cool looking.

Now the frame, including the motor butts, was 11.3 grams, but it was still far from a peppy flyer. Better start from scratch again.

First of all, the fully circular prop guards were a carryover from the original adaptation of the Inductrix, and served as much function as a vestigial tail or an appendix. They had to go.

Secondly, the curved connectors on the first frame got me thinking. I've been making big carbon frames, which is a relatively simple process – shave away material 'til it's too fragile, then put some back. Nylon, however, is flexy, and if you want a light and rigid structure you'll have to be a bit cleverer. I whipped up a frame where the diagonal members are thicker and meant to resist compression, and the horizontal and vertical ties are thinner and meant to resist elongation, like guy wires between a biplane's wings.

With some cutouts on the cam mount the frame was down to 8.11 g, and now it finally flew well. It was somewhere between a whoop and a mini, needing more roll than a whoop to keep it from sliding out in turns. But more than anything I was intrigued by the structure. It may look like an innocuous 3d printed part, but once you try to deform it its parts resist in either compression or tension, more like a living structure than a dumb rigid shape.

I know that this shape is identical to an XBR, but when it's made of a flexible material it behaves totally differently. The whole thing is way stiffer than 8 grams of nylon have any business of being.

The box frame holds its shape so much better 'cause three of the struts are in tension.

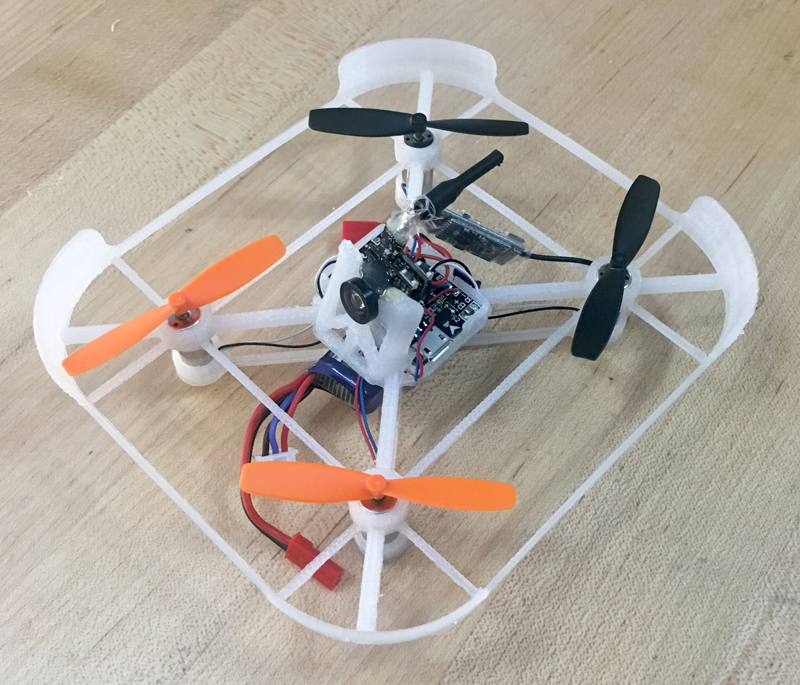

And here it is built up. I refined the FC snap, giving it deeper relief cuts for more flex, and an extension above that works as a handle to pull it back. I also added little hooks at the base of the diagonals to keep motor wires away from props.

For the 2s version I extended the same compression/tension idea to the prop guards, pushing them out with thick struts and tying them together with thin struts.

Sadly my ignorance of brushed motors bit me in the ass, and I burned out a motor in two batteries. 2s rated motors are on the way.

If you're interested in these babies here's a partial parts list:

Bigberg 1s:

Bigberg 2s:

Just make sure to get motors rated for your voltage. The STL's are here.

Babar

Once Bigberg was complete my thoughts naturally drifted back to Goldberg. The same changes would surely result in some weight savings.

Starting with a clean slate without ducts yields a 7mm smaller frame, and smaller = lighter. The basic structure came together fairly quickly, with estimates on strut thickness. The fc now mounts under tension with overhanging lips on the pegs. Now it just needs a cam mount. And since it's going to be lighter, it'll need more tilt, 20 degrees instead of Goldberg's 10.

The problem was that the frame was so pared down there were hardly any spots to anchor it. Furthermore, the smaller wheelbase brought the props closer together and left little room for the mount.

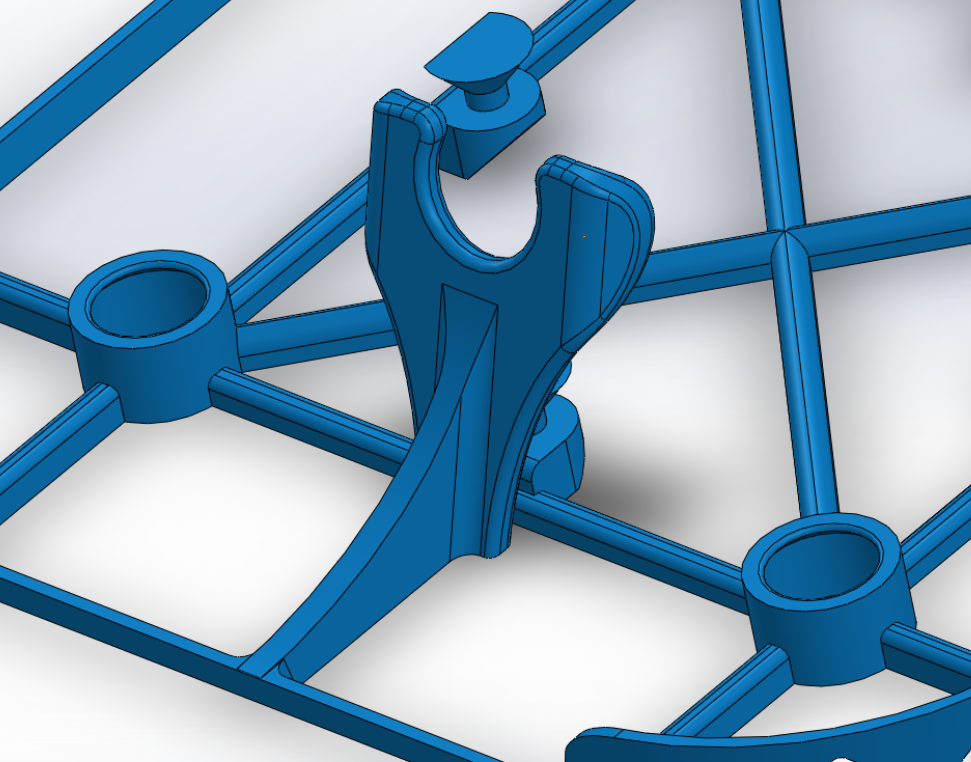

Goldberg's cam mount had angled flanges on each side to strengthen it and give it some rigidity:

I really felt the cam mount should be reinforced, so I came up with this. Above the props, there'd be the two flanges on each side. Below the props there'd be a central rib that bridged to the front strut. Another tiny rib bridges back to the middle strut. The rib and the flanges would overlap a little so the mount would not be an unreinforced flat stretch of nylon at any point.

The shape resembled an elephant head so it became Babar instead of Goldberg II. The battery holder/motor butt remained mostly unchanged, except for thinner walls and a slightly bigger opening for bigger batteries.

The first version was really stiff and HEAVIER than Goldberg, so I pared the struts down 'til the whole frame was 4.56 grams, just .8 gram heavier than the stock frame, and almost 2 grams lighter than Goldberg. And of course, like Goldberg, it has an integrated cam mount, struts, and battery holder, so there'd be no glue reinforcements, rubber bands, cam mounts, or canopies. The only thing you'd add to Babar is maybe a dab of hot glue to keep the fpv cam from rotating in its mount. After a few more iterations my complete build with the Acrowhoop v2 and Powerwhoop connector came to 20.2 grams without a battery.

This setup flew really nicely, a tad peppier than Goldberg. Some people were able to break the cam mount but mine has survived numerous crashes and is still in one piece.

I then discovered NylonX, a super stiff carbon/nylon blend that retains the resilience of pure nylon. I shaved the frame down even more, and got it down to 3.56 grams (just .34 more than stock). Finally I'm down below 20g.

If someone told me that one day I'd be scrounging around for .4 g savings...

Chris Griffin of Phoenix 3d will print and fulfill Babar. I'm still learning about nylonx and his prints are nicer.