Hevi/Thicc

Three people asked me for a 7” hex in the space of two days. I’m always game to design new things, so I took it as a sign and got cracking, even though I had no idea what the purpose of this frame would be. At the very least I wanted it to carry a Hero with no props in view, so I laid out the motors in a circle, but not as a symmetrical hexagon. I spaced out the front two motors a little wider to accommodate the Hero, then spaced the other motors evenly. After that the rest fell in place fairly easily. I gave the top plate some curves just because, and the everything else was dictated by the layout.

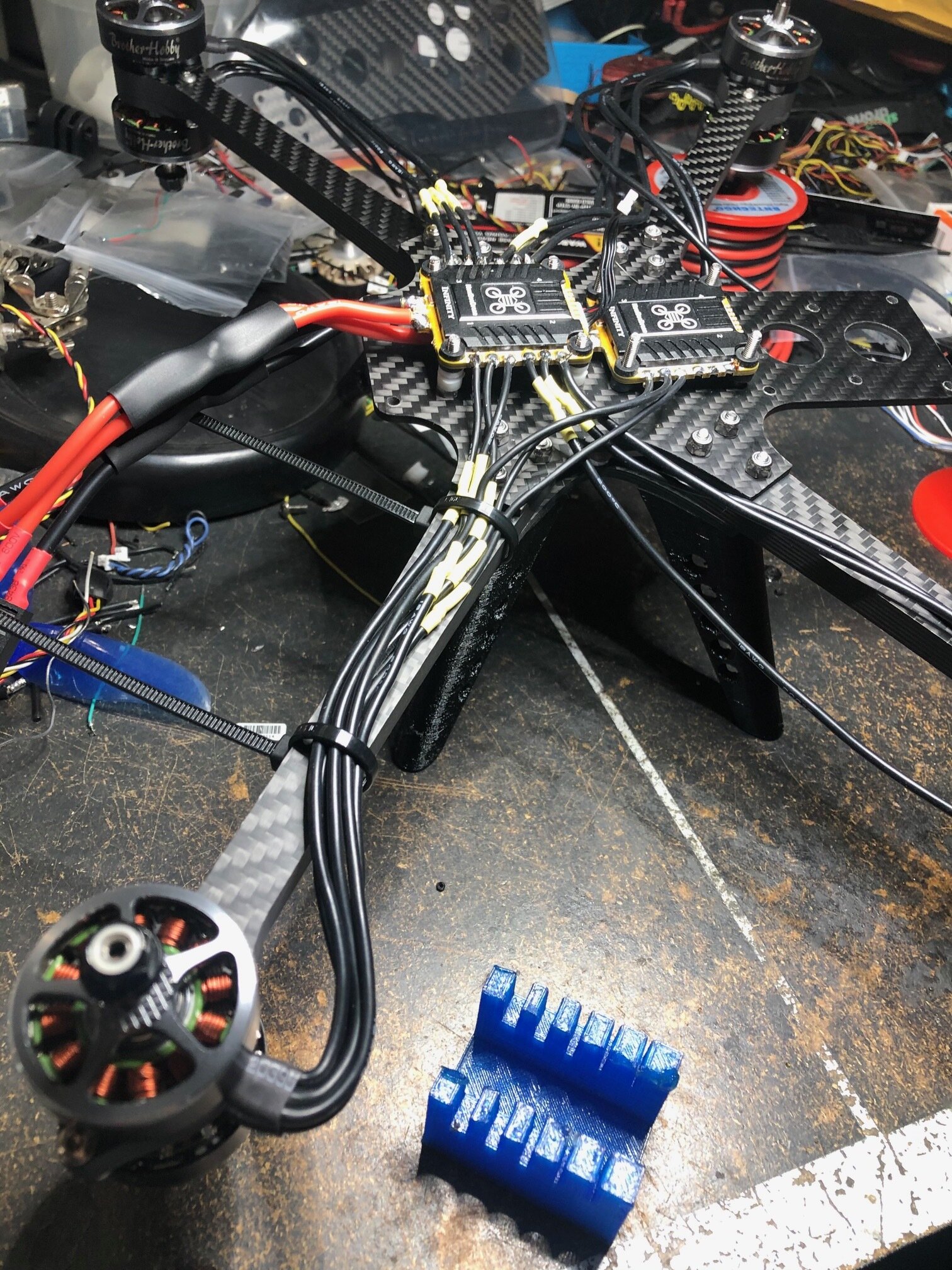

I built mine with individual esc’s and a Radix fc and power board, since the Radix has six motor ports built in. I didn’t initially install a 12v regulator for the DJI air unit, so for the time being it was a 4s only build. I also doubled up two esc’s on two of the power board’s four esc pads, since it’s a quad pdb after all.

Sharing is caring. The front and rear motors share pads on the power board.

I was a bit terrified to fly it, but aside from the knowledge that it was a big heavy death hexagon, flying it wasn’t all that different. And since some people care about flight times, I strapped a 5200 4s on it and flew the battery all the way down. It took 16 minutes and my back was screaming in agony by the time it was over. Should’ve sat in a comfortable position before taking off. Here’s the first six minutes, nothing earth shattering, just passing the time.

Fincky saw the frame and asked for one to fly a Black Magic. He flew it on 5 and 6s and it carried the load no problem, you can see a quick video of it here. I finally put a regulator in mine so I could play along. Fincky used a foam pad and lots of straps to mount his cam, but I wanted something a bit more…professional. It took me weeks of having it in the back of my mind before I came up with a good solution.

My idea was to mount the cam to a carbon plate using a 1/4-20 screw, the universal standard for cameras, and supplementing it with lots of straps. The carbon plate mounts to the frame with some big fat tpu dampeners, and the front dampers have multiple holes to change cam tilt angle.

It’s really hard to get under that plate to screw in the 1/4-20, so I made nylon printed thumb screws for more leverage.

For some reason I’m super proud of this simple little thing. You have to hammer the bolt in and then it’s super secure. Don’t over torque it!

Meanwhile, Gab got a look at Fincky’s setup and wondered if six motors are good, wouldn’t eight in an X8 configuration be better? And to be honest, this pissed me off a bit, ‘cause just when I think I’ve got something solved Gab has a knack for blowing things up and making me start from scratch. But then I thought about how Gab is smarter than me and how he has a ton of real world filming experience and how he’s coerced many cool designs out of me, and I relented.

I Do Gab’s Bidding

So, X8. For me, the biggest challenge with X8’s is how they all have janky tube arms and motor mount clamps. I’ve been cutting recesses in my 8 and 10mm thick arms, and it occurred to me that I could simply add a plate underneath the arm and let the screw heads sit inside the recess. Nice, simple, and low profile, with no clamps that can twist or slip.

And since this might be a thing, I better lay claim to it by naming it the Shen CatDog Mount.

I think you meant to say DogCat.

The other annoying thing about X8’s is that they require landing gear. I couldn’t conceive of an elegant solution for the longest time, ‘til Gab and I got on a video chat and I realized that the gear didn’t need to be that tall, and maybe they could be 3d printed instead of some crazy carbon configuration like I made for Derrick. And now that I got that out of the way, I could finally buckle down and start drawing.

The Hevi was conceived as a 7” hex with no apparent purpose but coolness, but now I could start anew and make this X8 a dedicated big camera lifter. Gab had a pretty specific motor spacing in mind, so I started with his specs and built it out.

I went with TPU landing gear, making them thick and with a U shaped cross section to make them strong enough. They’ll screw in where the arms attach to simplify things. The only other standout feature is a flared out top plate, so the cam mount carbon plate can have nice wide mounting points to keep the camera from rolling too much.

I’d intended on sending a proto to Gab and letting him do all the testing, since I’m not a working video drone pilot, and 8 motors + 2 4-in-1’s + fc + air unit = lots of $$$. But as the design came together I got more and more excited, and before I knew it I was ordering parts.

The carbon came in and I sent out one each to Gab and Nurk, and commenced building my own. Gab was traveling so Nurk was the first to finish, and I got to watch the maiden on video chat. He quickly put a dummy weight on his, flying acro moves.

My build, however, was cursed, as a faulty 4-in-1 had me on a wild goose chase for gremlins. I tried it with all NewBee Infinity parts, but it seems that the fc’s Uart’s wouldn’t remap as motor ports. I ended up with a Radix again, remapping TX4 and RX4 for motors 7 and 8. The crazy thing is the Radix only takes 5v to the board, so, on Nurk’s advice, I dug up an old fc to use as a 5v regulator. So that’s the power leads to a Fortini to the Radix, while a 12v reg goes from the power leads to the air unit. So. Clean.

I also discovered a mistake in the design. I’d drawn it up around 28mm motor bells, but I built mine with Brother Hobby 2806.5’s, which have 33mm bells. That meant the screws and locknuts for the lower motor mounts weren’t really accessible, which forced me to build mine with motors turned 90 degrees. So sad and ghetto.

4 motors are recycled, note all the splices. It’s a painful build.

I don’t have any big 6s batteries, so to save money I thought I’d use my 1050 6s’s in parallel. This actually works out pretty well, since I could wire power leads to each 4-in-1, and fuse the two leads midstream. If I was gonna fly this thing for real shoots I’d get some 2500 6s’s and put XT-90’s on them, but for me this setup was perfect.

The power leads to each 4-in-1 join up.

The rear 4-in-1 is elevated so the front 4-in-1’s leads can slip under it. With 2 spots for stacks I was able to build mine with 20mm standoffs, which will be critical to keeping that big ol’ camera close to the CG.

Gab finally got some down time to build his. He used a Lumenier Lux7 since it has 8 motor ports built in. He also informed me that he told me this ages ago but it went in one ear and out the other. I could’ve saved myself three days of frustration but apparently I’m really really dumb and don’t listen well.

So after the torturous build mine finally hovered, and Nurk was able to follow along on video chat the next day for the maiden (what a time to be alive). My buddy Justin Shaffer brought his Black Magic 6k and it handled the weight with no problem, hovering way below 50%. It flew incredibly easily but for the stress of destroying Justin’s camera. He only had a 40mm lens that day, so the footage isn’t terribly useful.

We returned a few days later with a large zoom lens, and it handled that as well, LOS footage above. The Tokina 11-16mm alone was 552g, making the full camera payload 1.5kg! Later I flew with Randy Slavin, and here’s a few short clips from his Black Magic 4k. This one’s unstabilized:

And this one has Warp Stabilization:

I got new arms in, so I got to rotate the motors and resolder them all over again. At least it’s finally cleaner.

Clean at last. Well, except for that Fortini in the back acting as a 5v reg. Also, check out them DJI antenna holders.

I will love her and hold her and call her Thicc. Never thought I’d be excited for an X8 but this thing is so cool. That’s the big ass 552g Tokina lens btw.

And, because I’m dumb, it wasn’t ‘til I got this thing designed and built that some of its benefits became apparent to me. With its tighter fore/aft motor layout, you can have lower cam tilt with no props in view compared to Hevi. Also, with two more motors and props, there’s more rotational mass for greater yaw authority. And finally, of course, the extra thrust. How odd, Gab was right again.

Given its benefits over the Hevi, I’ll be recommending Thicc to people looking to fly big cams. Hevi will still be available and supported, in case you prefer having fewer motors, or you want to be able to land in snow without burying four motors. This is kind of the Wild West of cine quads, with a lot fewer pilots flying Black Magics compared to GoPros (you can’t send out 20 frames and expect test footage from everyone in a week), so development will be ongoing. But as of now, I’m pretty happy with where the Thicc is.

Nurk Comes to Town

Nurk had an East Coast swing planned, so we worked in some Thicc testing while he was in town. Nurk brought his 4k and Justin his 6k, and we did a little formation flying.

That’s Nurk’s on the left. He also built it with parallel wiring for two batteries for maximum redundancy. He’s running Hobbywing 2408 1300’s, I’m running Brotherhobby 2806.5 1300’s. Mine was noticeably more powerful.

There’s fewer options for wide angle lenses for the 6k, hence the gigantic Tokina zoom.

Then Randy Slavin showed up on his ebike and Nurk did a little proximity chasing. Kudos to them both for some real closeups. Some footage here.

Portrait mode on an octocopter.

Meanwhile, Nurk started a ‘Thicc Bois’ group chat with testers Gab, Fincky, Ferdinand Wolf, and Jake Yubeta. One issue the boys all agreed on was that they didn’t love the fact that the TPU landing gear was sandwiched in the arm assembly. This reduced the pressure you could exert on the arms, which means they can wiggle a little bit. I didn’t think it affected flight performance, but imperfect is imperfect, so I started running through solutions. Nurk further complicated things with a request for removable gear for travel.

The last thing I wanted to do was move the landing gear out to the arms, as that would weaken the arms and ruin the aesthetics of the frame. I thought about having one screw bypass the TPU, making a carbon plate that replaces the washers, or printing the legs with a stiff filament. All were bad compromises. Then I got it. Use longer screws, and screw on the arms without the landing gear. I redrew the gear with recesses for nuts so that it can slip over the longer screws and attach with a second set of nuts.

The boys also had problems tuning pitch, and suspected the soft camera mount was the cause (it turned out not to be). I drew up new front legs for the cam mount and added adjustability for angle. This stiffens the mount up quite a bit, but we’ve yet to see jello in Black Magic footage so it’s probably ok.

Things Take a Turn

Fincky told us a friend recommended DAL7056 props, saying that they tightened up his tune compared to the HQ 743’s we were all running. I quickly got a set and headed to the field with Justin and his 6k. I must’ve did a bad job strapping in the batteries, ‘cause on they fell off on takeoff. My first crash with a Black Magic. Luckily everything looked fine so I took it back up, and it dropped out of the air about a minute later. While it was flying I noticed a lot of vibes in the fpv cam. We took the camera off and flew it with no issues, so the Black Magic went back on…aaand it crashed again. This time the lens took a beating.

The frame survived for the most part, only the TPU pieces under the cam mount sheared.

Here’s the gruesome video:

I went back out a couple days later with HQ props and flew it without a payload. No vibes, and smooth as butter. And a crash.

I strapped an 800g water bottle to the cam mount and flew it gingerly. Again, no vibes. So, ymmv, but I’m done with the DAL’s.

Gab told me that the Radix doesn’t support octo’s (just ‘cause you can remap UARTs as motor ports doesn’t mean it’s a good idea), so that was the most likely cause of my crashes. I rebuilt it with fresh Bardwell esc’s and a Lumenier Lux7, and I ditched my Fortini 5v regulator.

The connector on that Newbee esc shorted. I had two Bardwell’s on hand so I replaced them both. Better to have the peace of mind while flying someone else’s Black Magic.

As of this posting I have about 90 minutes of flight time on the new setup with no hiccups, so, fingers crossed, looks like the Lux7 is the way to go. Also, I’m not running rpm filtering, just to be safe. The fc’s got enough to do with an octo (I later learned it’s totally ok and now I have rpm filtering on).

Want one? You can order it here. Testing with cameras will be ongoing but the airframe is solid.

Things Go Sideways

Everyone was initially totally psyched with the Thicc, but slowly doubts crept in. Gab started noticing some low speed pitch wobbles he couldn’t tune out, and once he mentioned it other testers saw it too, to varying degrees. And with the absence of a great electronic image stabilization solution (like Reelsteady Go for Heros), a persistent wobble was unacceptable. I suspended sales and we started brainstorming.

One theory floated amongst the testers was that the rear motors were getting propwashed by the front motors. Since Thicc is a lot wider than it is long, I asked Gab to blackbox some slow forward and sideways flight, and sideways flight was cleaner, which lent credence to that theory.

I thought of a quick relatively painless way to test this. I drew up some legs with holes drilled askew so you could quickly change Thicc to a longer deadcat layout. Gab had CNC Madness cut him two arms and got it in the air.

Relocate two holes and you have a quick deadcat fix.

It flew better but the wobbles were still there. You can see it in the slow straight parts of this flight. Make sure to watch the whole thing to see some amazing and terrifying Black Magic acro (???).

With that promising result I drew up proper main body plates. I kept the deadcat layout (it moves the rear motors slightly out of line with the front props’ wash), and moved them back a further 20mm, for a total of 45mm more length compared to the original.

Of course, as the rear motors move back, CG moves back as well. I didn’t want to move the Black Magic back, since that starts to bring props into view at low cam angles. So instead I extended the bottom plate so you can move the battery back to balance out the camera. This adds room for a second battery strap, either for more security for one big battery, or the ability to mount two smaller ones in tandem.

I like this a lot more than stacking the two 1050’s.

So I ordered the plates, and then a pandemic happened. The factory was kept closed for an extra three weeks after Chinese New Year. They finally got the plates cut and sent off to their forwarder in Hong Kong, where it sat for another three weeks awaiting a plane. Then it got to New York, where it sat for another week. Once I got them I sent them to the test crew, where, as of this writing, half of them are still in transit after two weeks.

Meanwhile, I got mine switched over (extending 12 motor wires, yay!). My first furtive flights (at 3am on my my deserted street) were ok, but I was struggling with the tune. Then Gab mentioned that he was very happy with a Troy Naquin tune, so I got the file from Troy. I also sat my lazy ass down and attended Bardwell U for a quick Blackbox primer.

Now, I haven’t been flying during New York’s lockdown. I’ve been arrested for flying before, and while the charges were dropped I still spent four hours in the drunk tank (filled with actual drunks). Needless to say a stint in the drunk tank now is sub optimal. My solution was to ride out before sunrise and get my tests done before 6am. I flew with 1.2kg of dummy weight and a Hero7.

The first flights with Troy’s tune (he works with Mark Spatz, Christopher Thomas, and Robert Moss) were amazing. I could see no wobbles whatsoever in the goggles and the craft held its angle really well on punchouts. I got home, loaded it in the Blackbox viewer and it was every bit as good as I thought. You can try Troy’s tune here (thanks Troy!). I’m on Betaflight 4.1. I’d love to try this on 4.2 but my board freezes up when I try to flash it, so it’s 4.1 for now.

The gyro’s tracking the setpoint really well, and the i term’s barely doing anything. I got some logs from Troy with the same tune on the original geometry, and the difference is pretty apparent.

Slow hands off pass above. The gyro doesn’t deviate from setpoint by more than 1 deg/s, and the i term isn’t fighting any bias in the craft’s flight tendencies. The deviations are pretty random, so I think it’s the craft responding to outside disturbances.

A faster pass. Still tracking well, but the i term is pitching back. I have no idea why this is, as inefficient rear props and more aero drag up top would pitch the craft back, so you’d expect to see i in the positive range.

Here’s Troy on the original geometry. You can see the wobble in the yellow gyro trace. It’s persistent and seems to have a regular frequency, which indicates to me that it’s intrinsic to the craft itself.

And here’s Gab on the intermediate geometry, which is slightly extended and deadcat, on a slow straight pass. The result is pretty much between mine and Troy’s.

Here’s another way to look at it, comparing pitch p, setpoint, and gyro to roll p, setpoint, and gyro. This is more apples to apples in case one of us was flying in windier conditions.

Me, both traces pretty quiet.

Troy, pitch much wobblier than roll.

Gab, right between me and Troy.

Justin told me he had no issues flying in Brooklyn, so I rode out to do some testing with his Black Magic 6k. I’d already crashed his cam a couple times weeks ago so I got in two mellow flights with shaky fingers and we got out of Dodge.

Fincky’s plates were the first to get delivered and finally someone else could try the new layout. As you can see it’s working well for him too. Keep in mind he’s using a wider, less expensive ‘practice’ lens, so he’s getting props in view.

So, as of right now (May 18th) the plates are ordered and being cut. Unfortunately, shipping from China has been incredibly inconsistent, so I’m hoping I’ll have them in hand in a week or two but I can’t guarantee a ship date. I’ll post again when I have them in hand.

Gab Nails It

After a while it became apparent that the frame was just one small part of equation in terms of getting perfect footage. The dampers are critical, and seem pretty specific to each pilot’s setup. SteadXP is critical as well, but it’s hardly plug and play. Gab, after much work, put it all together.

12/29/20 Update

Just a quick note. I now recommend the Matek F722HD. You can plug 2 4in1’s directly, 32mb flash blackbox, and no bec needed for the Air Unit. Makes for a super easy and clean build.

2/14/21 Update

Sergi Ros wanted a safe drone that could carry over 2kg. One option was to make a ducted 7”, but it would be so large that unobstructed camera angles would be hard to achieve. It occurred to be that I could very easily make Thicc ducted by making the lower motor mounts double as the duct holder as well.

The upper prop is 5”, and since the duct tapers outward the lower prop will be a bit more than 5”. I used a bullnose 5” on top, and cut down HQ 743’s for the bottom.

The lower prop is about 136mm (it’ll vary depending on your stator height). That’s a cut down HQ 743.

I’d sold my original Thicc, which is just as well since it had motors for 7” props. I wanted to build this one up properly with higher kv motors for 5”, Xing 2806.5 1900kv. I gave it a hover inside and OMG was it loud. Like, ear damage loud.

Since the onset of Covid I’ve taken to doing late night street flights. The roads are deserted so it’s an easy way for me to get in a quick test. I armed, took off, and landed right away. It was so loud I fully expected to have the cops called on me. My daughter heard it from her room at the back of the apartment on the third floor. So it was off to the field for a quick test. I did a couple quick flights and hightailed it out of there before park rangers could be called. The good news was that it handled a 2.1kg payload with ease, very much capable of Squirt-style flying.

Nurk wanted to play along, so I sent him parts to modify his Thicc.

His ended up being able to carry about 1.5kg comfortably, since he was using his existing 7” motors. Still, with the super light BGH1 he could do cool stuff with it.

So, it kinda works and it kinda doesn’t. It can carry a lot of weight and fly more safely around people, as long as your definition of ‘safe’ doesn’t include hearing loss. If you have an application for it the motor mounts are here, and the duct file is here. There’s also a prop cutter in that listing so you can cut the lower props.

Thicc 2.1

Thicc’s cam mount was always a bit ghetto. I never bothered to make something better because a: I got busy with Siccario, and b: Gab and Sergi Ros both made some nice mounts, and I saw no reason to cut into their sales unless I could make something significantly better and/or different.

Then I made the universal mount for Siccario, and there was just no reason not to adapt it to Thicc. All the upper parts stay the same, only the base plate needed to be changed.

I gave the top plate circular bumps so the dampers would be fully supported. The original top plate totally works, this just buttons things up nice.

And here it is all together. The DJI antennas have to go downward now to avoid the cam mount. The antenna mount has a sharper curve to clear the lower props.