Flaco

Skinny skinny frame.

One of the scenarios we often discussed is that if race purses got big enough, frames would eventually become like F1 cars – super high performing in the air but unable to take any impacts at all. I tucked that thought away for future use, thinking that I wouldn't have to create something as ludicrous as a 'disposable frame' for a while.

Then Racekraft posted pics of their Screamah, and it was clear that it would be, dare I say, a game changer. Less drag, less weight, more thrust, and yes, totally not meant to last a very long time. Skinny arms are going to be a thing, and there'd be no sitting on the sidelines for me.

I'm against structural FC stacks, so I'll start with the same standoff spacing that Mixuko and FTB use. I drew up 5x5mm arms that butt up against each other, and identical minimal center plates to hold everything together.

Just two screws per motor, we're saving every gram here.

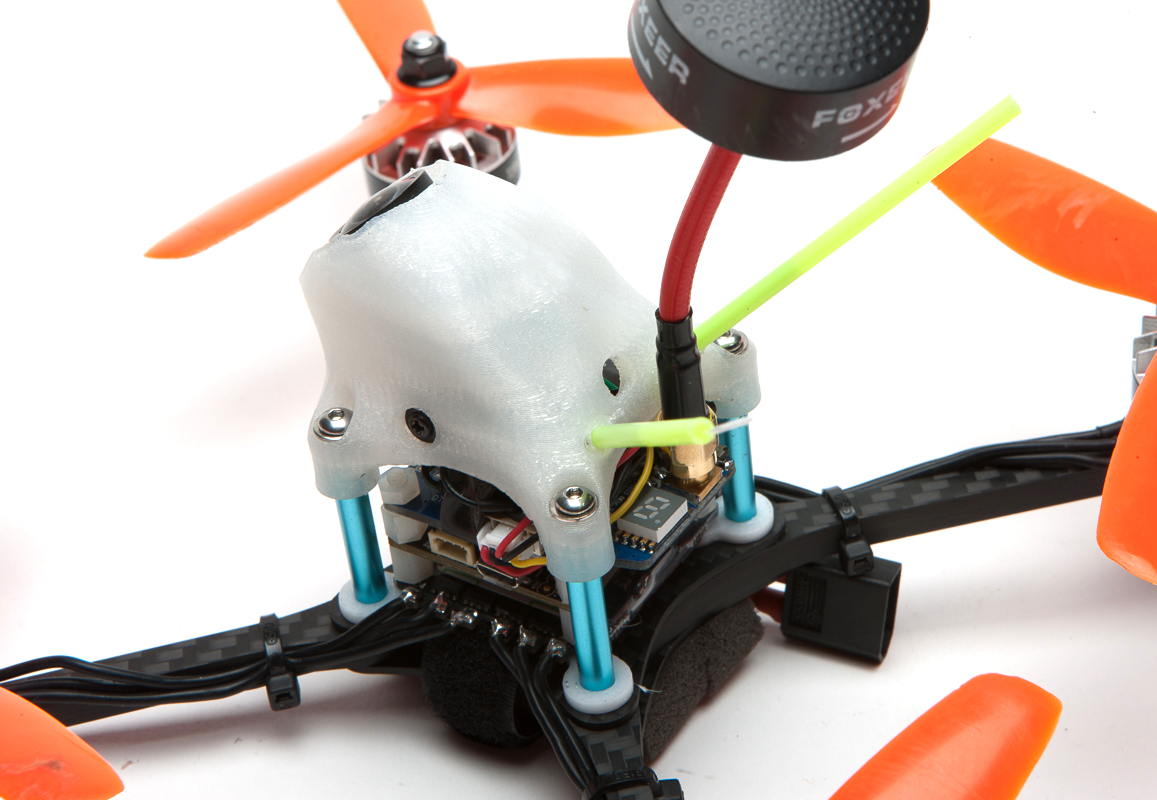

This frame would take all the existing tops, but I felt it needed something special. I whipped up something to hold the cam, intended for a pigtail SMA or stackable VTX. The loft created some unintended cool looking ridges on its back which I then played up. It had a nice organic feel so I dubbed it the Facegrabber.

This seemed like a pretty good plan, but then the carbon showed up. The arms wouldn't screw in without some filing, and it became clear that this design relied too heavily on perfect tolerances. Too loose and the arms flop around, too tight and you have to break out the file. And of course, file down too far and the arms are ruined.

We built up the frames and flew them anyway. Mine suffered from a defective Matek and wouldn't go full throttle. Steve and Mike loved theirs, and promptly blew threw several arms. We built them with Aikon 30's, but it really needed a 4 in 1 esc to realize its full potential, so we all pre ordered some 30a's and waited for them to ship.

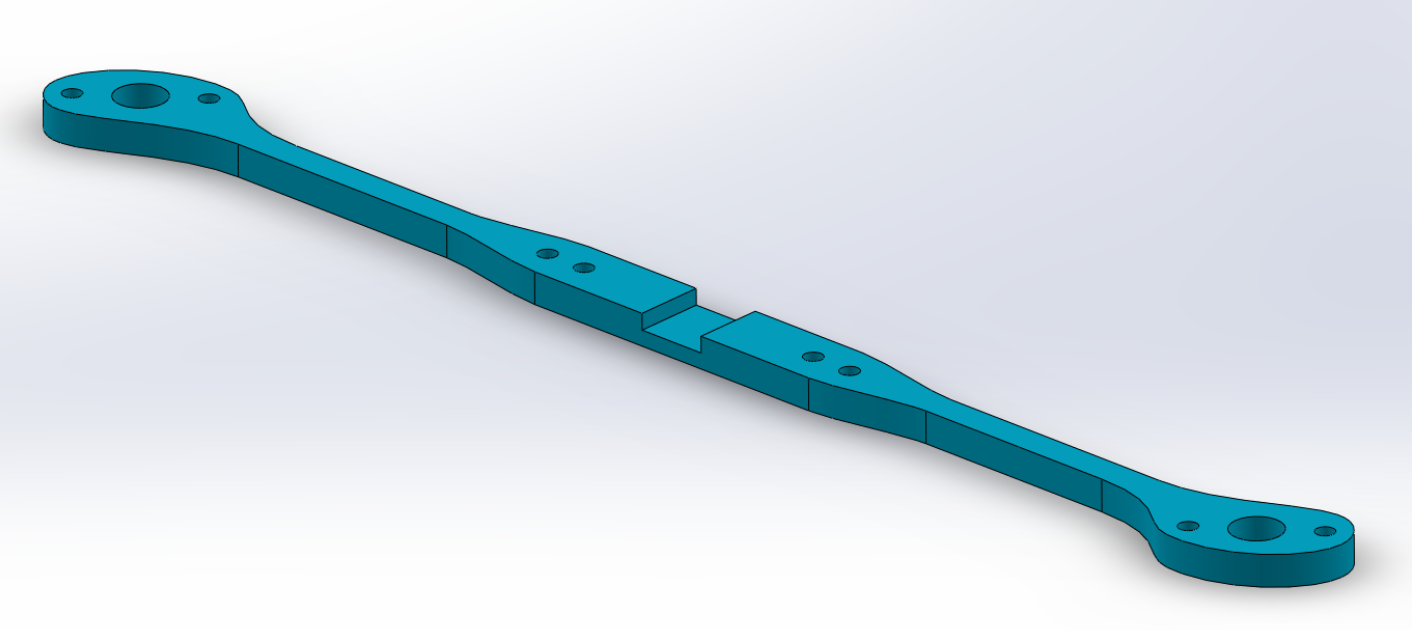

Meanwhile, I went back to thinking about the arms. I now had a set of parameters that I didn't even realize existed when I began. The design had to work regardless of tolerance, and it had to be wiggle-free. The original arm did have two mounting holes, but they're too closely set to eliminate play. After much thought I came up with this.

There'd be two versions of the arms, one with the channel cut out of the top, the other out of the bottom. The channel is purposely cut a little wide and deep, so the arms are guaranteed to fit over each other. Now the screw holes are set nice and far apart, greatly reducing the amount the arm can wiggle. There were a couple drawbacks, however. Break an arm and you have to dismantle the whole quad, and you need two different arms as spares.

My 4 in 1 finally arrived and I built mine up with a Kombini, Diatone stackable VTX, and Tornados. It flew exactly as I'd hoped, crazy fast and easy to pull out of dives, instantly locked in on Betaflight 3 defaults.

Meanwhile, something else was happening. This was always meant to be a disposable frame, where arms snapped like twigs at the expense of performance, but they were snapping at way too high a rate. As far as I could tell, they were breaking two ways. One, simple high speed impact. Two, the arms are so thin they twist easily, and normal use delaminated the carbon 'til the arm was a noodle. I suspect gyroscopic precession from motor rotation was doing the twisting. I can accept arms that break on high speed impacts, but not arms that turn into noodles just because there's a motor spinning on them. So the next batch will be 6x6mm.

Then on a bike ride back from flying, a new idea hit me. I forgot about it by the time I got home, but fortunately it bubbled back up a few hours later.

Now I have four identical arms again, but with mounting points spread out further, reducing play. And if one breaks you can slip it out without dismantling the whole build. The carbon came in and I was very pleasantly surprised. With just the outer screws attached, the frame was almost perfectly rock solid. The arms keyed into each other, and even though I intentionally left a tiny gap between them, the keys were far enough from the pivot point that the arms barely wiggled. This was exactly what I was hoping for: loose tolerances between the arms so there's no chance that someone would have to file it to make it fit, but very little play once assembled.

Next I started thinking about arm replacement, because these aren't meant to survive many impacts after all. You have to remove one outer screw and one FC stack screw to replace an arm. The outer screw is no big deal, but there'd be a nut or spacer under the FC stack, and once you remove that screw that nut could fall away, and it'd be hell to line it back up. This is not something you want to deal with between heats at a race. My first thought was to create a single gasket between the four FC screws, but the strap needs to pass through that gap. So instead I drew up a part that served as a 2.5mm spacer for two screws, and anchored it to the standoffs. Arm changes should be a breeze now.

And now there's a groove down the middle for the strap.

The funny thing is it's rock solid on the outer screws, and a bag of bones on the inner screws. Or maybe it's a folding frame.

But wait, there's more! With the pod being made of flexible TPU, that leaves each standoff left to fend for itself on impacts. If the pod was rigid, then all four would resist impacts together, and you'd get less bent standoffs. Now that Chris Griffin has mastered printing nylon for the Mifune, I asked him to give the Facegrabber a go.

The new version flew wonderfully, and it'll take us a while to bash it and see how well it holds up. The hard mounted SMA on that Diatone VTX snapped as expected, so I switched to a pigtail version.

Things Take a Turn

I was thinking that now I had a super aero frame and a super light frame, but never the twain shall meet. Then it struck me, why not make fairings for the arms?

On the Mifune, I didn't create a full teardrop cross section because: A, it's super difficult, and B, a 25mm wide arm would make a gigantic and heavy airfoil cross section. But with skinny 6mm arms, I could do a TPU wrap that's a reasonable size. My first idea was to make it two-piece, with the top piece wrapping around the arm and the lower piece locking onto the top. I got it looking pretty good after a few iterations, but there's no avoiding a bump in the seam, which isn't a great thing for an airfoil.

Hated to drown this one in the tub, it fit together so well.

So idea #2 was to make it one-piece, with a split down the lower half. 3mm nylon bolts will hold the bottom halves together, push them in and then nip them flush.

Now that I finally have a trailing edge, why not take care of the motors too. I drew up some motorbutts to press fit onto the arms. I made them really thin-walled to keep weight down. I glued them on and took it out the next day.

Now it's some kind of praying mantis looking thing.

Amazingly Flaco flew twice as fast with the wings and butts!! Or not? Intuitively this should reduce drag and increase thrust, but my guess is that it's at a magnitude that would be very difficult to verify. I was glad to find that there were no strange effects from the wings, probably because airflow under the props travels mostly along the wings regardless of which direction the quad is traveling (propwash speed > air speed). The motorbutts made me laugh and glowed when backlit, but the glue job quickly gave way.

Ok, so it's kinda cool, and it might be faster. But it's a crappy two piece design with one piece that's glued on, totally unacceptable. The butt should integrate seamlessly with the wing, and stay in place without glue. My first idea was to have the wings extend and sandwich the butt, and screw the two together. After more thought it seemed possible to make it all in one piece, if only it would slip over the motor.

This was another fun part to draw up, a loft intersected with a revolve. I gave the bottom of the wing a curve to make it prettier, and thickened its chord as it transitioned to the motor. After four iterations I got a nice looking part that JUST slips past the motor.

It's a tight squeeze. No way it's falling off.

Now we are doing the speaking, yes?

Integrated wings killed the Motorbutts. I really wanted a product called 'Motorbutts'.

The wings added 40 grams total. If you want to run light you can just pry them apart and pull them off. The nylon screw stays attached to one side and can be reused. Personally, I'd use them almost all the time – they protect the arms and motor wires, and provide a nice base for takeoffs and landings, and they look cool. Take them off for tight courses or windy days.

With the integrated wings/butts Flaco flew three times as fast. Amazing. (No it didn't.)

@zoomas.fpv set up a technical track, and that gave me ample opportunities to crash test Flaco. The arms were undamaged. More importantly they lost no perceivable torsional rigidity, which suggests, for now, that they should be less susceptible to gradual deterioration than the 5mm arms. The wings separated and slid in crashes, but were easily reset.

I also took a bad line into the tree tunnel and drilled a tree head on, breaking the Facegrabber. It was a hard enough hit that breakage was expected, but I was glad to see that the FC stack was untouched, so hopefully that means the Facegrabber was stiff enough to bear the brunt of the impact. Also, it broke vertically, which means that Chris his print settings dialed, with good adhesion across the layers.

@control.fpv flew the 6mm arms without wings, and loved the stiffness. He also finished the day with his frame intact, something that never happened with 5mm arms. @bluetoothxp flew his headfirst into @ledboy's Full Tilt Boogie, with this suprising result.

The aerial high-five left FTB with a broken arm, and Flaco with a half broken arm. That's a moral victory for Flaco.

In the weeks that followed @control.fpv took a couple of wins with Flaco, and no one broke an arm. @zoomas.fpv even put a Zoompod on his, and so far the arms have handled the extra weight.

I also picked up another team pilot, Ark Nabbit, lover of 4" frames. So naturally there had to be a 4" Flaco. The increased efficiency of the Flaco versus the Mitsuko let him run smaller batteries on the same course, which reduced the pendulum effect, which made life easier for the motors, which made it more efficient, which...

I used a really long steel M3 screw for the FC stack, with 3d printed TPU spacers. I like how clean and strong this is.

Ark filed his arms to take 1806 motors, so 4" arms will have M3 holes added to accommodate them.

So...

The original goal was to create an superlight disposable frame. Flaco didn't turn out to be the lightest frame around, but it's way stronger for it. It also retains almost all the performance gains of super skinny frames 'cause those gains are more tied to increased thrust than decreased weight. You can run it as a light frame or as an aero frame. Preorder is here, the wings will be available on a print to order basis from Phoenix 3d.

Streeetch

Of course right away people wanted a stretch Flaco. Part of the elegance of the original design was the fact that only one arm was needed for spares, and I couldn't think of a way to keep that for the stretch format. So after weeks of mulling I succumbed and did this:

Now there's two different arms, one slightly straighter than the other. And if you don't build it right you could end up with a dead cat!